Tokyo-based Jun Mitsui & Associates has converted an abandoned grocery store into a sake brewery in Upstate New York in partnership with US studio Pelli Clarke & Partners.

Located in Hyde Park of New York’s Hudson Valley, the 55,00 square foot (5,110 square metre), complex will host spaces for rice washing, drying, steaming and fermentation for Dassai Blue Brewery, the New York location of the Dassai sake brand.

“Dassai Brewery is designed to harmonize beauty and functionality,” said Pelli Clarke & Partners partner Fred Clarke. “Visitors are invited to observe the brewing process in an environment that blends modern and traditional aesthetics as well as the built and natural world.”

The site contains three buildings – the brewery, housed in the shell of a former Stop & Shop grocery store, a small rice polishing building and a wastewater treatment facility.

Jun Mitsui & Associates and Pelli Clarke & Partners sought to marry elements of Japanese architecture with small-scale manufacturing and its location in upstate New York.

“Because the site is located in the Hudson River basin and is under extremely strict scenery controls, we paid great attention to maintaining harmony with the historic atmosphere of the surrounding streetscape,” said Jun Mitsui & Associates.

“Partly because the client was a Japanese brewer who mainly makes sake, we also incorporated ‘Japanese-ness’ into the design.”

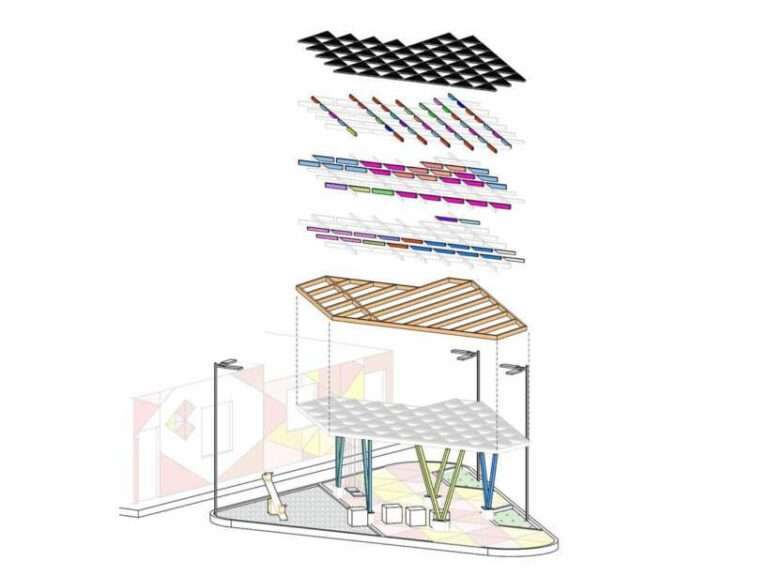

The main brewery building is rectangular, with wide-tin-covered eaves wrapped around its entrance that create a covered walkway along its length.

According to the team, it was informed by the Engawa, an element of Japanese architecture that resembles a veranda or porch that runs along the perimeter of a structure.

“The main building has a porch space with long eaves that links with canopy-style roof design, which serves to accent the exterior,” said Jun Mitsui & Associates.

“We have created a Japanese-style porch design that not only continues the interior space for tasting drinks, etc. and the landscape as an intermediate area, but also gently welcomes visiting guests.”

Floor-to-ceiling windows line the front of the building, which leads into a tasting room for visitors.

The building’s brewing facilities are located at its centre and are available to view during tours through several picture windows.

The production layout takes advantage of two pre-existing loading docks, moving in a “counterclockwise flow”.

“The brewery seamlessly fits into the building’s footprint with production following a counterclockwise flow from two loading docks,” said Pelli Clarke & Partners.

“Polished rice moves from the northeast facility building, progressing through production steps, culminating at the southeast corner for bottling and shipping, utilizing the pre-existing loading dock.”

The rice polishing building sits across a parking lot and landscape designed by Reed-Hilderbrand, which incorporates private seating nooks and Cherry trees informed by traditional Japanese gardens.

The building is smaller in stature and is lined with Yakisugi charred cedar cladding with a gabled roof and two overhangs that mirror the eaves of the main brewery building.

Here, the fatty outer layer of the grains of rice are stripped away using automatic grinding machines, leaving behind a starch interior that will be converted into sugar during the remaining brewery process.

Carpenter + Mason fuses Japanese and industrial elements for Brooklyn Kura sake bar

Carpenter + Mason fuses Japanese and industrial elements for Brooklyn Kura sake bar

The remains from the process are taken to the brewery building through a loading dock located on the side of the building.

Other elements of the brewing process include long, wooden tables housed in a hot room that are used to create Koji, or moulded rice, which is then blended with other ingredients to create a yeast starter for the remaining process.

The brewery currently uses Yamada Nishiki rice imported from Japan for its sake, although it currently is working with Isbell Farms in Arkansas to produce the specific species in order to reduce the carbon footprint of its sourcing.

The project is part of an initiative of the Culinary Institute of America to “further the education and awareness of sake within the United States,” according to the team.

“We hope that this facility will become part of the broadcast of Japanese culture into other countries and will grow up together with the local American culture,” said Jun Mitsui & Associates.

Pelli Clarke & Partners has worked extensively in Japan and recently completed Japan’s tallest skyscraper.

The photography is courtesy of Pelli Clarke & Partners

Project credits:

Design architect: Jun Mitsui & Associates

Architect of record: Pelli Clarke & Partners

Architect project team: Jun Mitsui, Fred Clarke, David Coon, Mark McDonnell, Masa Ninomiya, Ileana Dumitriu

MEP engineering: Fitzmeyer & Tocci

Structural engineering: Gibble Norden Champion Brown

Landscape architecture: Reed-Hilderbrand

Civil engineering: Chazen Labella