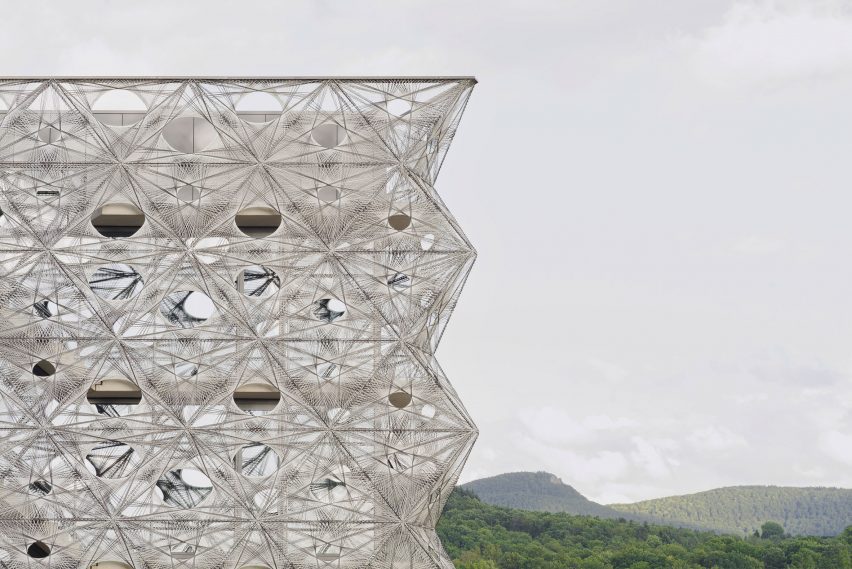

A web of glass and carbon fibres envelops Texoversum, a university building for textiles that architecture studios Allmannwappner and Menges Scheffler Architekten have created in Germany.

Located in the city of Reutlingen, Texoversum forms part of the Reutlingen University of Applied Sciences campus expansion and contains offices, workshops, a university store, collaboration areas and a CNC robot workspace.

Its woven facade design is informed by textile construction and was developed by Allmannwappner and Menges Scheffler Architekten with engineering practice Jan Knippers Ingenieure.

“The fibre facade is an integral part of both the architectural expression of the building as a textile research and innovation centre and the environmental engineering and related indoor comfort strategy of the project,” Menges Scheffler Architekten partner Achim Menges told Dezeen.

Texoversum’s facade is composed of triangular panels measuring approximately four metres in width and 1.5 metres in height, each made by a robotic winding process developed at the University of Stuttgart.

There are five types of panels, each sharing the same triangular outer shape but varying slightly to create corner pieces and different-sized openings in the centre.

Manufactured by FibR GmbH, the web-like panels are made from white glass fibres overlayed with black carbon fibres that add structural support.

As the production is bespoke, no production waste or material off-cuts were produced, according to Menges.

“Fibrous filaments are freely placed between two rotating winding scaffolds by a robot,” explained Menges. “During manufacturing, a lattice of white glass fibres is generated, onto which the black carbon fibres are placed where they are structurally needed.”

“In this process, the predefined shape of the building component emerges only from the interaction of the filaments, eliminating the need for any mould or core,” continued Menges.

He said this process results in a “bespoke form” and a “highly distinct architectural appearance” for each component.

University of Stuttgart creates biomimetic pavilions based on sea urchins and beetle wings

University of Stuttgart creates biomimetic pavilions based on sea urchins and beetle wings

Texoversum’s facade tiles, which are self-supporting, have a staggered arrangement. This creates a multi-layered effect that shades the internal spaces while also providing openings with views out of the building.

“The fibre facade constitutes the external sun protection of the building, which has to fulfil stringent shading requirements in compliance with the German building code,” said Menges.

“The white glass fibres serve as a formwork for the black carbon fibres, which provide the necessary structural capacity,” added structural engineer Jan Kippers.

“It is a pure fibre structure that spans from floor to floor and allows cantilevers of around four metres at the upper edge without a steel frame or similar.”

Inside, Texoversum has a split-level design. A central atrium separates the building into two halves, with each side separated in height by a half-floor level.

It has an industrial internal appearance with an exposed concrete structure and ceiling ductwork and an open-plan layout to encourage collaborative working.

The robotic winding process used for the facade has previously been used in designs for pavilions including the Elytra Filament Pavilion at London’s V&A museum and the BUGA Wood Pavilion at the Bundesgartenschau horticultural show in Germany.

According to Menges, Texoversum was the first time the robotic manufacturing process was implemented in the design of a permanent building.

“While we had successfully built several temporary structures before, Texoversum constitutes the first permanent building using this design and manufacturing approach,” he said.

“As Texoversum is a permanent building, we had to meet the full requirements of German building authorities,” added Kippers.

“For this, extensive tests had to be carried out to prove the long-term creep behaviour, weather resistance, fire resistance and others.”

Other buildings with facades made by robots include an art gallery in Shanghai’s West Bund district by Archi-Union Architects and a winery in France’s Rhône Valley by Carl Fredrik Svenstedt Architect.

The photography is by Brigida González.