The latest edition of our weekly Dezeen Agenda newsletter features this year’s Don’t Move, Improve! awards shortlist. Subscribe to Dezeen Agenda now. Annual awards programme Don’t Move, Improve! has revealed its shortlist for this year’s competition, hosted by New London Architecture…

In the bustling city of Bangalore, India, The Villa Tabebuia stands as a serene, Zen-inspired sanctuary with a contemporary Japanese-style designed by TaP Design Inc. The vision behind Villa Tabebuia was to create a space that exudes tranquility and elegance…

‘the veil’ unveiled in shenzhen In Shenzhen, China, Groundworks Architects has completed The Veil, a city lounge offering a workplace and escape from the busy urban environment. The project’s sinuous, minimalist architecture stands in stark contrast to its industrial surroundings.…

Milan Design Week 2024 visitors who stopped by the 100R exhibition had the chance to see how aluminum scrap can be turned into coveted design objects that are ready for mass production. Norwegian aluminum and renewable energy company Hydro is…

House in Hokkaido is a minimalist home located in Hokkaido, Japan, designed by Jun Igarashi Architects. The design revisits the traditional “shop house” concept where commercial spaces and residential areas intermingled, creating a dynamic street life. This architectural approach reflects…

Mixing wood tones in your home can seem daunting at first, but with a few key strategies, it can create a warm and inviting atmosphere. The secret lies in balancing the undertones and the grain patterns of different woods. By…

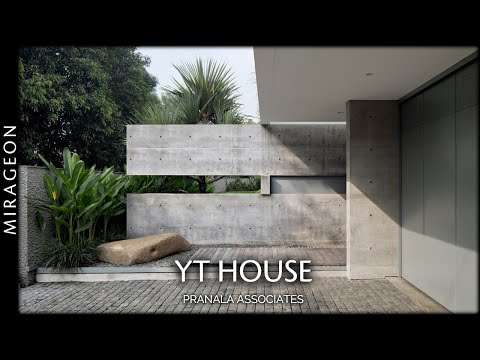

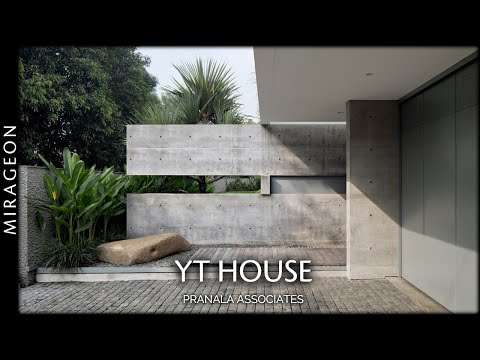

The YT House is a residence located in the south of Bandung that emphasizes privacy through the strategic use of trees to obscure the external view. Designed by Pranala Associates, the house is characterized by an emphasis on privacy, offering…

…

Joshua Weissman’s home was inspired by the work of renowned Austin architect, A.D. Stenger. Want even more AD? Subscribe to the magazine and get a free tote ►► Still haven’t subscribed to Architectural Digest on YouTube? ►► Read…

PANTONE is the universal language of colour for designers, brands, and manufacturers. Therefore, it’s safe to say the Pantone Colour Institute holds a lot of sway when it decides what’s hot. Since starting in 1999, the company’s trend forecasting of…

🏠 Explore the world of tiny homes with our latest video: “Tiny House Listings for Sale Under $50K You Can Buy Now”! Dive into the details of various tiny homes listed for under $50,000, from mobile units to eco-friendly abodes,…

How can an eclectic twist on mid-century decor style redefine a home? Our latest feature story reveals one such transformation, where bold, eclectic accents meet sleek forms. Step into this eclectic mid-century modern home where every detail contributes to a…

Huge is no stranger to working with big ideas. The digital agency shares that it “creates products and experiences that grow ambitious brands,” including clients like Google, M&M’S, LEGO, TEZOS, Adobe, and more. It only makes sense that the environment…

Creating a picturesque garden involves more than just planting your favorite blooms; it involves designing a path that invites you to enjoy every corner. Stepping stone walkways are not only functional, preventing wear and tear on your grass, but they…

Dezeen has teamed up with DesignMarch to livestream a day of talks on the role of architecture and design in addressing global imbalances. Watch the concluding session here from 2:30pm London time. DesignTalks is a programme of panel discussions that…

Cast Corbel House is a minimalist residence located in Norwich, United Kingdom, designed by Grafted. The renovation of the Victorian home was driven by the need to accommodate a large family that frequently visits. Grafted restructured the primary living spaces…

This house was designed to seamlessly integrate with the lush tropical nature surrounding it. Its spacious and transparent spaces invite constant communion with the outdoor environment, while its intelligent architectural solutions, such as large openings and high ceilings, provide cross…

If there’s one thing we in the design community can agree on, it’s that fast furniture cannot be depended on to last. Its mass-produced nature and often lower-quality materials tend to deteriorate quickly over time, leading to environmental waste both…

Inside the Zennihome Denizen, a 320 square foot prefab home with a base price of $90,000.00.…

Today, AD travels to Phoenix, Arizona, to tour the David and Gladys Wright house—the home designed by architect Frank Lloyd Wright for his son. When your father is America’s most celebrated architect, the greatest gift he could give you is…