Rapid prototyping — now more commonly known as 3D printing — has been around for a while now. At industrial scale, it’s become increasingly agile and refined, harnessing a growing range of materials and replicating manual or mechanized processes. With these advancements periodically trickling down, the still novel technology has also become more accessible and far less cost prohibitive for everyday hobbyists. With FibreSeek’s FibreSeeker 3, which recently launched on Kickstarter and will soon begin shipping, performance and durable application is also now attainable by everyone.

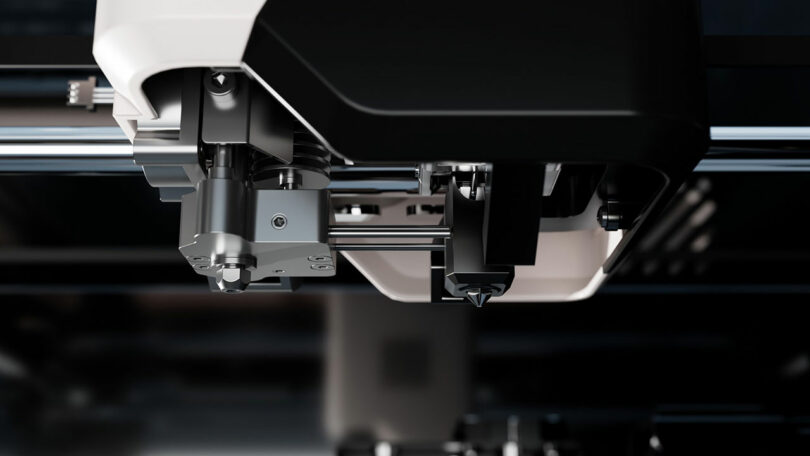

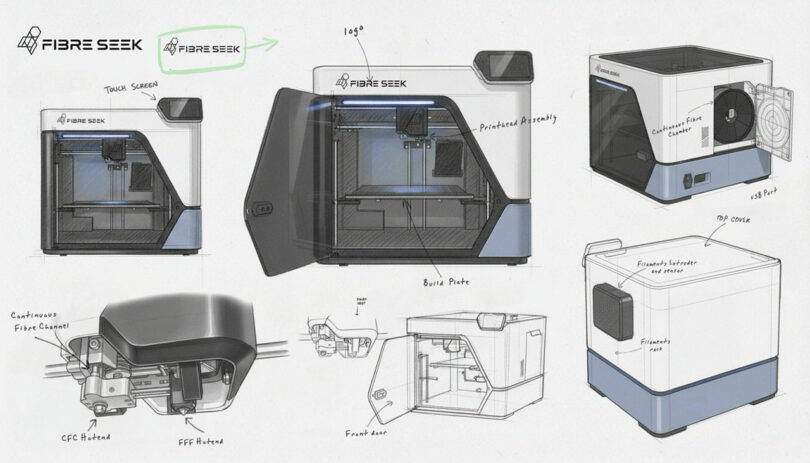

The compact, sleekly encased desktop printer is the first consumer-grade continuous fibre device of its kind. It has a tensile strength up to 900MPa, print speeds of up to 500mm per second, and a 300×300×245mm build volume. FibreSeeker 3 filters endless strands of carbon and glass fiber into melted thermoplastic, printing reinforced structures with up to twice the strength of aluminum but half the weight. It’s ideal for custom-creating elements that can replace metal components in disrepair: those found on aircrafts, robots, and cars, but also kitchen appliances, even furniture, and home accessories.

“FibreSeeker 3 transforms what used to be factory-only technology into something anyone can use,” says Ryan Liu, FibreSeek CEO. “It’s industrial power in personal form.”

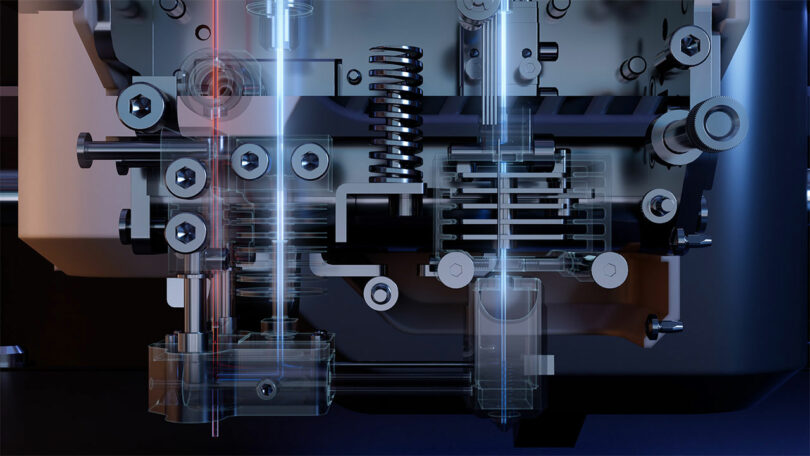

The small but mighty printer operates in three ways. While the High-Speed Mode (FFF) function achieves up to 500mm per second for fast prototyping, smooth finishes, and decorative prints, the High-Strength Mode (Hybrid) combines plastic and fiber reinforcement for sturdy, lightweight components (best suited for robotics). Hyper-Strength Mode (Full Fiber) prints with nearly full continuous fiber, producing parts with up to seven times the durability of standard plastic.

If that wasn’t enough, FibreSeeker 3 is also equipped with industrial-level safeguards: an integrated 720p intelligent camera for real-time monitoring; breakage and clogging sensors for both plastic and fiber; and a closed-loop cooling system for precision control that keeps the device below 149 degrees.

All of this can be managed through an easy-to-use 5-inch touchscreen and computer app. The integrated Aura Slicer Suite seamlessly transforms 3D models into optimized geometries with near precision placement (just 0.2 mm of give). Taking into account other environmental factors—that of home set-ups or classrooms—FibreSeeker is especially quiet.

To learn more about this innovation, please visit kickstarter.com.

Photography courtesy of FibreSeek.