From Stone Walls to Skyscrapers: Understanding Structural Masonry

The Monadnock Building in Chicago began construction in 1891 and is still in use today. The building features a somber facade without ornamentation and a colossal height – at the time – of 16 floors. It is considered the first skyscraper built in structural masonry, with ceramic bricks and a granite base. To support the entire load of the building, the structural walls on the ground floor are 1.8 meters thick, and at the top, 46 centimeters. One hundred and thirty years later, this construction system remains common and allows for the erection of taller buildings with much thinner walls, accomplishing even new architectural works economically and rationally. But what is structural masonry about, and how can designers use it in architectural projects? And for what kinds of buildings is this system most suitable?

The act of stacking stones to build walls was used in iconic historical buildings such as the pyramids, the Parthenon, the Great Wall of China, the Notre Dame Cathedral, and many others. Some of these buildings continue to intrigue researchers regarding how they were built and how they still stand. To draw a timeline of structural masonry is to approach the history of architecture and its great works. Briefly, masonry is a construction system in which the walls of the building perform a structural function, using masonry, bricks, or stones, in a way that is self-supporting. Stacked in layers, the components may or may not be connected by a binder (mortar) that heavily influences the mechanical properties of the wall. Such mortars can be made of lime, cement, or synthetic adhesives.

Currently, stone walls are still being built, but much more for their aesthetic aspects than for being the only viable structural option, as was the case in ancient times. Experiments, research, and new technologies have allowed designers to create blocks strong and light enough that they are simple to build and highly resistant. In the 1940s, masonry blocks started to be manufactured industrially and sold on the market. Today, there are ceramic, concrete, soil-cement, and sand-lime blocks for the construction of masonry buildings. The blocks also are shaped in a way that make them resistant to compression efforts, and are drilled for structural reinforcements, concrete, plumbing, and electrical ducts.

Unlike the column-beam system, which is more common today, in masonry, the walls will distribute the load to the foundation and later into the ground. The success of the structure is determined by the geometry and arrangement of these structural walls, resisting the structure’s own weight and occupancy loads (vertical loads) as well as lateral loads caused by wind, for example. It is essential that the vertical planes work together so that the loads are evenly distributed and that no wall becomes too fragile. This is done through the correct dimensioning of spans and spaces, and the placement of openings in suitable locations.

Masonry can be structural or load-bearing. While the first type is a little simpler, wherein walls are built only in blocks and mortar, the load-bearing masonry is reinforced by wires, bars, or steel screens, dimensioned to resist active forces. These reinforcements are placed in the cavities of the blocks and, later, filled with grout (a type of concrete or mortar with high resistance and high fluidity).

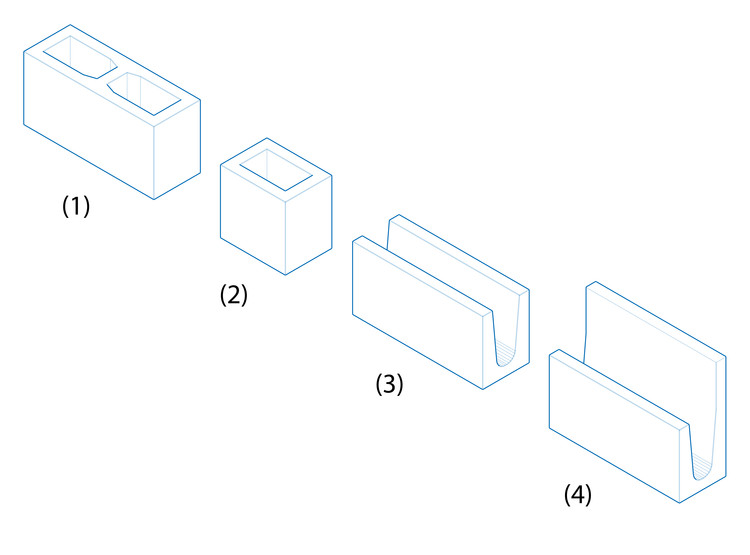

Different types of blocks fulfill specific functions in each project. There are different patterns around the world, but in general, there exist common structural blocks (1 and 2), which have already been mentioned above, and gutter-type blocks (3), which receive horizontal reinforcement. There are also some blocks that allow the slabs to fit together, often called “J” channels (4). In this typology, the slab rests on one end, providing structural locking and a good finish. As the blocks have great dimensional regularity, this greatly improves the efficiency of the project and the successful execution of the work.

The main advantages of using this system are in the speed of construction; reductions in the use of wood, steel, and concrete; saving time and cost; highly organized construction sites; and good fire resistance. This construction system also leads to a rationalization of the project and especially other construction elements, such as electrical and hydraulic installations. In addition, masonry has high compressive strength and is often aesthetically attractive when left uncoated.

Evidently, the supporting walls must not be removed without the replacement by another element of equivalent function, which can be a disadvantage, as it greatly reduces the flexibility of the building and makes it almost impossible to make radical changes to the original architectural layout. Another issue is that masonry buildings do not fare well in areas with frequent earthquakes. In these cases, it is essential to understand and follow local legislation.

Today, there are examples of load-bearing masonry buildings reaching up to 28 floors high. The system can be suitable for building types ranging from small single-family buildings to large structures. In general, the masonry project presupposes an integration between all aspects of design and construction, and the architects need to show leadership and exercise control for the work to be executed properly. Obviously, having the support of structural engineers during the process is essential. Masonry does not allow improvisation and design changes during the construction work. Masonry is an extremely old structural system that nonetheless, through successive technological contributions, can be highly desirable for the cities of the future.